H2 Fuel Cells

“Using a fuel cell is the optimum way to regain the energy stored in hydrogen. It converts the chemical energy directly to electrical energy and heat in an electrochemical process.”

(Source: Deutscher Wasserstoff- und Brennstoffzellenverband, https://www.dwv-info.de/)

There are different types of fuel cells that are for example used in the fields of automotive, domestic households, uninterrupted power supply and for applications in astronautics. Amongst these different types, H2 fuel cells belong to those that are becoming ever more relevant concerning the current energy and mobility sector developments.

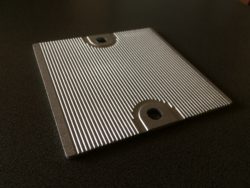

Bipolar Plates for H2 Fuel Cells

We, at CREMER, build thermal process facilities that are suitable for high temperature sintering at temperatures of up to 1400 °C. By the addition of modern equipment such as rapid cooling units the thermal treatment of the compacted parts can also be integrated in the thermal process plant.

One example of the products for which our thermal process plants are applicable are compressed components made from stainless steel powder, amongst other things so-called Cr-plates, that are used in fuel cells as bipolar plates. In order to sinter components at up to 1800 °C the CREMER Walking Beam Sintering Technology WBS has for example established a good reputation. Based on our CREMER Pusher Plate Technology we can also offer a thermal process plant explicitly adapted for oxidation under pure oxygen.

By adapting our established thermal process plant technology explicitly to the process parameters needed for fuel cell components, we can and plan to make a valuable contribution towards increasing the economic feasibility of the promising fuel cell technology. This, according to our main field of expertise, is especially relevant for all components that can be produced using powder metallurgical methods.

If, therefore, within either a funded or company internal project your aim is to increase the economic feasibility and competitiveness of the fuel cells technology, then we could be the right partners for you. Our contribution could be to help achieve this aim by increasing the availability of the powder metallurgically manufactured components (e.g. bipolar plates) needed to produce high quality fuel cells. Please feel free to contact us.

Please feel free to contact us. CREMER has more than 50 years of experience in developing, constructing, commissioning and maintaining tailor-made thermal process plants.