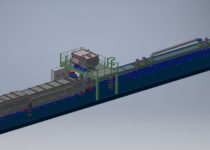

Roller Hearth Sintering Furnace RHF

Roller Hearth Furnaces are used for applications where conveyor belt furnaces cannot attain the required maximum temperature. These furnace types are characterized by high througphut. The parts are loaded onto CFC or graphite charge plates (possibly passivated through small ceramics). The roll drive combined with the use of charge carriers allows varying the speed at which the parts are run through the furnace system. Thus, the parts can be driven quickly from the sinter zone into the rapid cooling in order to harden them precisely.

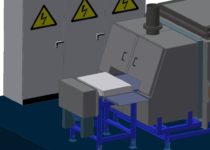

Also, using charge carriers allows the installation of locks to optimize protective gas consumption and for flow control.

In combination with a conveyor belt furnace design in the cooling zone, linked to an annealing or tempering zone, a modern and efficient furnace is constructed meeting all process requirements of today’s market.

- Temperature under protective gas up to 1.300°C

- Throughput 200 – 500kg/h sinter