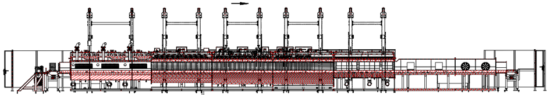

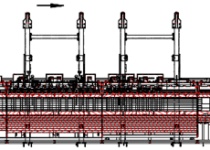

Pusher Plate Sintering Furnace for Oxide Ceramics

The sintering furnace for oxide ceramics, which is suitable for process temperatures of up to 1680 °C, is electrically heated and has two parallel pusher plate lanes for high throughput rates. The thermal debinding is an integral part of the thermal process of this plant. This pusher plate sintering furnace is therefore an attractive alternative to the tunnel furnace plants for this application currently on the market. This is especially true if the oxide ceramic products can not be allowed to come into contact with off-gas from burners and have to be fired carefully with the help of a precisely controlled furnace process temperature. Various accessories and different configurations allow an individual structure with proven serial parts. For example, in case lesser throughputs are required, a one-lane pusher plate configuration is possible. The two-lane pusher plate sintering furnace is not only interesting from a technological view-point, it also represents a commercially interesting solution for a variety of application fields.