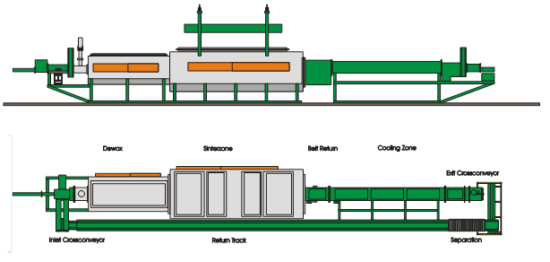

Pusher Plate Sintering Furnace for Non-Oxide Ceramics

The pusher plate sintering furnace for non-oxide ceramics, which is suitable for process temperatures of up to 1680 °C, has a gas-tight modular construction and is electrically heated. The thermal debinding zone is an integral part of the thermal process plant. Airlocks at the intake zone and outlet zone safely ensure that air cannot enter into the furnace. This thermal process plant is also suitable for the thermal treatment of powders and granules, especially for calcination, reduction or infiltration. Various accessories and different configurations allow an individual furnace structure with proven serial parts. The pusher plate sintering furnace for non-oxide ceramics is not only interesting from a technological view-point, it also represents a commercially very interesting solution for a variety of application fields.