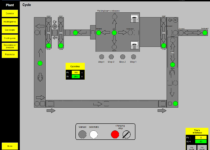

Walking Beam Sintering Furnace WBS

In applications at high temperatures combined with high throughput rates, Walking Beam Furnaces come into action. The parts lying on charge carriers are run through the furnace. The walking beam is a transport vehicle of utmost smoothness. Thus, the walking beam furnace combines the advantages of roller furnaces with those of pusher furnaces. It is highly accepted for Fe-PM parts sintering, MIM, and even refractory and heavy metals and fuel element sintering.

Frequently, different furnace approaches are combined: stearate zone = pusher furnace, HT zone = walking beam, rapid cooling = roller furnace, cooling zone = conveyor belt furnace. This way, a highly efficient high temperature sinter furnace for Fe-PM is modelled.